Introduction

Serial tendering in construction is a complex concept, but it’s an important one to understand. It helps contractors work together and bid for projects more efficiently – leading to better outcomes all around. This article will delve into the details of serial tendering and how it can benefit everyone involved in the construction industry.

For those new to the topic, serial tendering is essentially a process where multiple contractors are invited by a client or contractor to submit bids on parts of their project. These parts may include separate works packages or even individual elements within larger contracts. The aim is that each bidder gains insight from previous submissions, while still being able to offer competitive prices without sacrificing quality workmanship.

By breaking down big projects into smaller components that can be outsourced, clients get access to greater expertise at a lower cost. Contractors also have increased flexibility when bidding for jobs as they don’t need to commit to taking on the entire contract themselves – instead, they can pick and choose which parts they want to do best fit with their skillset and schedule. Read on for a deeper understanding of serial tendering in construction and why it could make your life easier!

Read More: 5 Popular Types of Tendering: Pros and Cons

Definition Of Serial Tendering

Serial tendering is a system used in construction tendering. It involves submitting multiple bids for the same project, one after another until an acceptable bid is accepted by the employer. Serial tendering allows employers to obtain multiple offers from various contractors and compare them with each other before making their decision.

This process also helps ensure that all potential bidders are given an equal opportunity to submit a competitive offer. As such, it can be beneficial for both parties involved in the tendering process. By utilizing serial bidding, employers can make sure they get the best value for money when selecting a contractor and that they receive quality workmanship at reasonable prices.

The main advantage of serial tendering is that it gives employers an effective way to assess different contractors on several levels – not only looking at how much they charge but also evaluating things like their past performance or expertise in specific areas related to the job in question. Additionally, as there may be many bidders competing against each other, employers will often find themselves able to negotiate better rates than if they were dealing with just one contractor alone.

In this way, serial tendering provides employers with more control over who works on their projects and what price range they should expect for services rendered. Moreover, thorough assessment during the process further reduces the likelihood of any issues arising afterward due to poor choice of contractor or inadequate specifications provided by them.

Overall, serial tendering provides numerous advantages for employers which help ensure that their interests are adequately protected throughout the tender selection process and beyond. With these benefits firmly established, we turn now towards exploring some of the particular advantages and disadvantages of serial tendering for the employer.

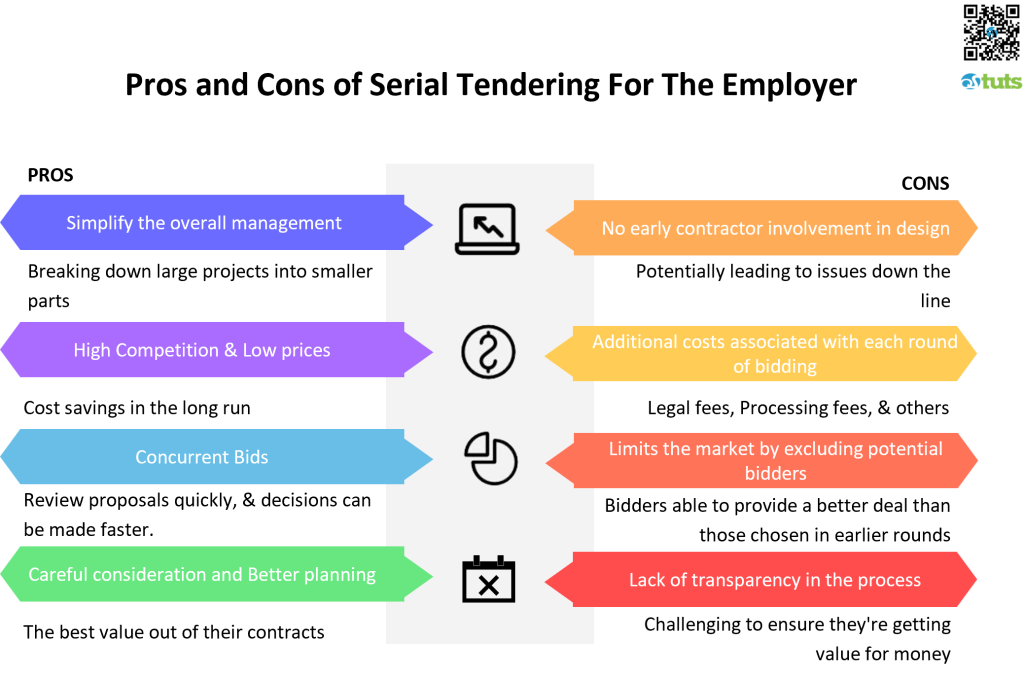

Advantages Of Serial Tendering For The Employer

At first glance, the concept of serial tendering in construction may seem like a nightmare for employers. Believe it or not though, there are actually some benefits to taking this route! Cost savings, time efficiency, and streamlining processes are just some of the advantages that can come from using serial tendering.

To begin with, one of the main reasons employers often choose to use serial tendering is its cost-effectiveness. Serial tendering allows employers to break down large projects into smaller parts which makes them more affordable and easier to manage financially. Additionally, because each part is only bid on by a few contractors at once, competition remains high and prices stay competitively low. This ultimately leads to significant cost savings for the employer in the long run.

In addition to being budget-friendly, serial tendering also saves time during the bidding process. Instead of waiting weeks or months for responses from multiple bidders all at once, concurrent bids allow employers to review proposals quickly as they come in over a shorter period of time. As a result, decisions can be made faster, and work on projects can get underway much sooner than traditional methods would permit. In other words, if you’re looking for an efficient way to speed up your project timeline then serial tendering could be what you need!

Finally, employing serial tendering helps simplify the overall management of larger projects by breaking them down into smaller tasks according to specific phases and stages. By allowing contractors who specialize in certain areas to focus solely on those aspects of the job it eliminates room for confusion among parties involved while ensuring that deadlines will be met without any major issues arising throughout the course of completion.

Serial tendering offers many advantages when used correctly; however, it’s important that employers take their time researching different options beforehand so they can make sure they’re getting the best value possible out of their contracts. With careful consideration and planning ahead of time most problems associated with implementing this method should easily be avoided altogether. Moving forward though now we must consider how these same advantages might present themselves as disadvantages instead.

Disadvantages Of Serial Tendering For The Employer

Serial tendering in construction can be disadvantageous for the employer. The process is costly and time-consuming, as the employer must go through the tender process multiple times with different contractors. This incurs additional costs such as legal fees, processing fees, and other expenses associated with each round of bidding. Moreover, it limits the market by excluding potential bidders who may have been able to provide a better deal than those that were chosen in earlier rounds; this could ultimately result in an unsatisfactory outcome for the employer.

Another key downside for employers is that serial tendering does not allow them to take advantage of any early contractor involvement during the design stage of their project. Early contractor input can help save money on materials and labor which would otherwise be wasted due to poor planning or incorrect calculations. Without this input from experienced professionals, there could be major issues down the line when attempting to complete a project under budget or even on time.

The lack of transparency involved in serial tendering also means that it’s difficult for employers to gain insight into why certain bids are being rejected or accepted throughout the process. This makes it challenging to ensure they’re getting value for money without knowing exactly what criteria were used to make decisions regarding awarding contracts. Consequently, employers are at risk of making ill-informed choices if they opt for serial tendering instead of traditional open competitive procurement approaches.

Overall, while serial tendering allows employers greater control over selection processes and decision-making within projects, its disadvantages render it less attractive than traditional methods from an economic standpoint. As such, careful consideration should be taken before opting for this approach. Moving forward then, we will discuss some advantages for contractors when using serial tendering in construction projects.

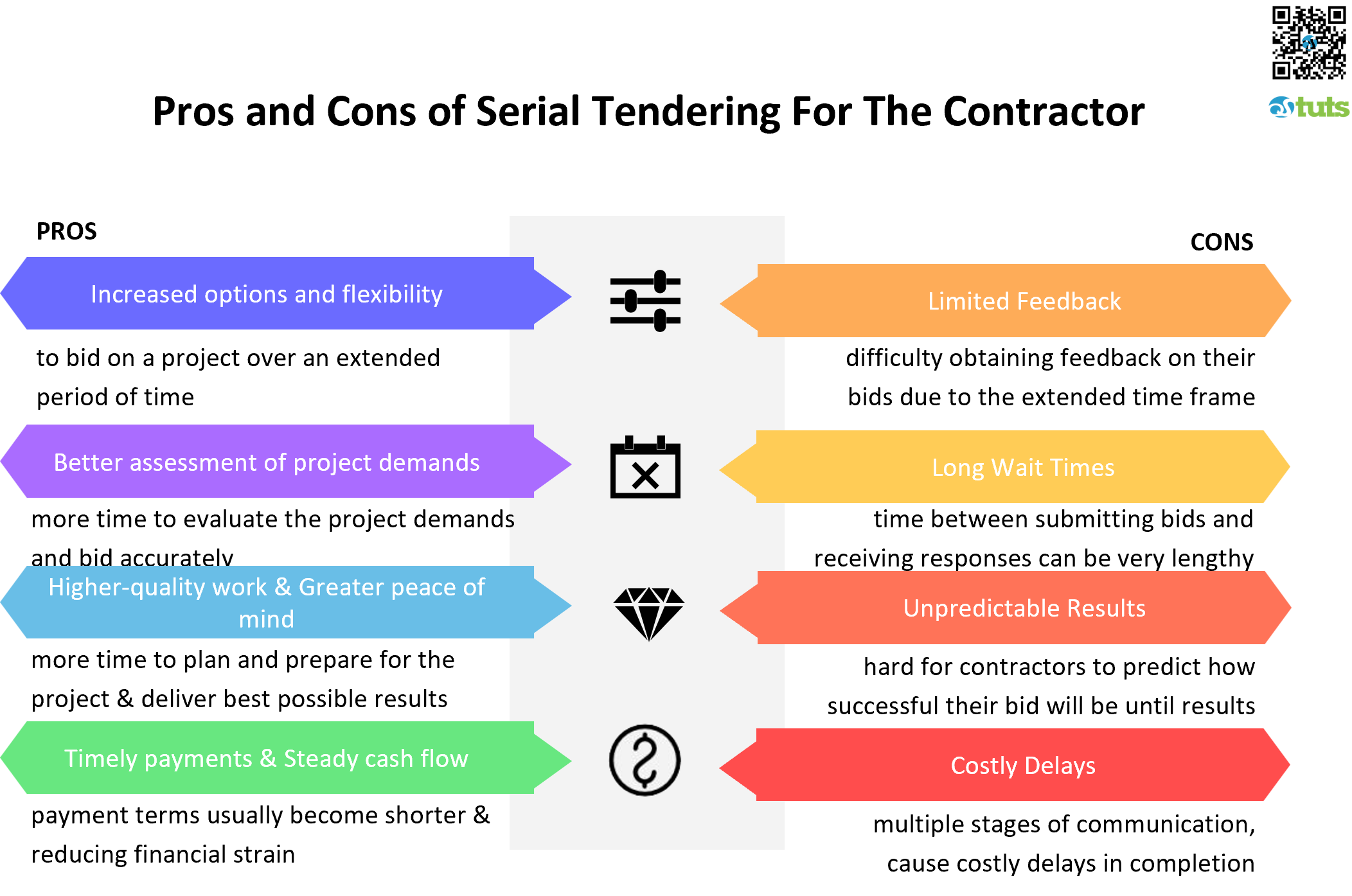

Advantages Of Serial Tendering For The Contractor

Although the employer may have a few disadvantages to consider when using serial tendering in construction projects, contractors also benefit from this type of process. As with any job opportunity, having more options and flexibility is always desirable for contractors – serial tendering increases both of these elements significantly. Through its ability to draw out potential bids over an extended period of time, it allows contractors to better assess the project demands and ensure that they are submitting their best bid possible. This increased visibility often leads to higher-quality work being completed as well.

One other advantage for the contractor that comes from employing serial tendering is timely payments. Since the amount of contracts available can be broken up into smaller increments, payment terms usually become shorter too; meaning less wait time before invoices get paid out by employers. With fewer delays between job completion and invoice payments happening concurrently, cash flows remain steady throughout each phase of construction – allowing workers to focus on completing jobs quickly without worrying about additional financial strain or losses due to late payouts.

The advantages provided by serial tendering provide a clear path forward for contract workers who want to make sure they’re getting the most out of every project they undertake. These benefits create greater peace of mind for everyone involved in a given job, ensuring no one gets left behind during the building process. From improved workflow efficiency and greater visibility into project demands to flexible bidding options and reliable funds transfer cycles-contractors can trust that their needs will be met with this methodical approach towards procurement management.

Disadvantages Of Serial Tendering For The Contractor

Serial tendering can be a challenging process for contractors. There are several disadvantages that should be taken into consideration before committing to the procedure.

- Costly Delays: Serial tendering requires multiple stages of communication, which can cause costly delays in project completion and ultimately affect profitability.

- Limited Feedback: Contractors may have difficulty obtaining feedback on their bids due to the extended time frame associated with serial tendering processes, making it difficult to identify areas that need improvement or understand where they went wrong in the bidding process.

- Long Wait Times: The length of time between submitting bids and receiving responses can be very lengthy, especially when there are multiple rounds of communication involved in serial tendering procedures. This can leave contractors feeling uncertain about the status of their bid and create anxiety over whether or not they will receive an award from the project owner at all.

- Unpredictable Results: With so many factors influencing decisions throughout the serial tendering process, it’s hard for contractors to predict how successful their bid will be until results finally come back – if ever!

This unpredictability makes long-term planning difficult, as any number of changes could occur during this period that could jeopardize a contractor’s chances at winning an award or negatively impact profits earned from completed projects. The legal considerations surrounding serial tendering must also be understood prior to engaging in such a practice.

Legal Considerations

Despite some of the disadvantages for contractors, serial tendering in construction has its own set of legal considerations. According to a survey conducted by the European Commission, over 70% of public procurement contracts are awarded through serial tendering processes. As such, it is important to understand the legal implications that may arise from this form of contracting.

The primary concern lies with bid submission procedures and compliance with relevant rules and regulations. All bids must adhere to the requirements laid out in each contract document before they can be considered for review or selection. This includes ensuring proper documentation is submitted as well as meeting any financial requirements associated with bidding on a specific project. Failure to comply could result in disqualification which would then require additional resources and time spent reviewing other potential bidders.

Another point to consider when engaging in serial tendering is how competitive pricing will affect overall results. Lowest price bids oftentimes prevail but there may also be instances where quality or service plays an essential role in determining who wins the award. It’s important to evaluate all options carefully before making a final decision so that you select the best talent while still remaining within budget constraints.

By understanding these key legal points related to serial tendering, construction firms are better able to make informed decisions about their projects and ensure successful outcomes going forward. With these considerations in mind, companies can benefit from exploring the benefits of serial tendering over traditional tendering processes more efficiently.

Benefits Of Serial Tendering Over Traditional Tendering Processes

Serial tendering offers many benefits over a traditional tender process in the construction industry. Firstly, it streamlines the overall process by reducing time spent on sourcing and evaluating suppliers, which can often take up to several months. This allows projects to be completed faster, allowing for better project optimization.

Secondly, serial tendering reduces costs associated with market research and evaluation of potential contractors or subcontractors as only one supplier is invited to bid per round. Lastly, it encourages greater collaboration between stakeholders due to its collaborative nature; this ensures that all parties are working together toward achieving the same goals and objectives.

This contrasts strongly with traditional tenders where multiple suppliers compete against each other in an open bidding system, leading to increased competition amongst them and driving down prices but also potentially sacrificing the quality of service or product provided. Serial tendering avoids this pitfall while ensuring streamlined processes throughout the entire procedure from start to finish. It provides a more transparent way of assessing bids without any bias towards certain suppliers based on their reputation or history within the sector.

The advantages of serial tendering over traditional tender systems make it highly attractive for those involved in construction projects. As such, understanding these benefits is crucial for successful implementation and overcoming challenges posed by implementing serial tenders in construction projects.

Challenges In Implementing Serial Tenders

Ah, the age-old tug-of-war between convenience and complexity! While serial tendering offers many advantages to a construction project over traditional approaches, it does come with its own set of challenges when implemented. In this section, we explore some of these potential issues that may arise in the construction industry due to serial tendering.

First, the level of competition among bidders is greatly reduced compared to traditional tenders. Because only one bidder can win at any given time, other contractors’ chances are significantly diminished if they don’t get selected for the first package or two. This could cause fewer bids overall on a particular tender, thus leading to increased costs and decreased value for money.

Second, as projects become increasingly complex and multi-stage packages overlap each other, there is an increased risk of double payment or missed payments occurring during implementation. For example, if a contractor has been paid for their work under one package but then fails to deliver on another package in a series of contracts that are closely related, it might be difficult for them to obtain additional payment from the client until the entire project is completed.

Finally, stakeholders must ensure that all relevant criteria have been taken into account when evaluating serial tenders so that decisions are made objectively without bias towards certain companies or individuals who may be involved in multiple packages within the same tender process. A failure to do so could lead to legal repercussions further down the line. Without proper evaluation criteria in place before entering into any agreement regarding serial tendering processes – both parties will likely face difficulties throughout implementation. With this understanding firmly established about challenges associated with serial tendering, let us now look at how best we can evaluate such scenarios moving forward.

Evaluation Criteria Of Serial Tendering

Bid evaluation criteria are used to assess the tenders submitted for a construction project. The tender evaluation criteria help determine which bidder is best suited for the job and can offer the most value-added services. These criteria include technical ability, financial capability, experience in similar work, and quality of products or services offered.

| Criteria | Description |

|---|---|

| Technical Ability | Measures expertise in executing the proposed works |

| Financial Capability | Assesses the bidder’s capacity to finance their operations and complete the works on time with minimal disruption due to financial constraints |

| Experience in Similar Work | Evaluates the contractor’s past performance related to similar projects they have undertaken before |

| Quality of Products/Services Offered | Reviews material specifications, equipment provided, and other services associated with bid submissions such as warranties and guarantees when assessing the quality of products/services offered by bidders for the construction project |

It is important that comprehensive bid assessment criteria be established early on so that all bids can be evaluated fairly according to predetermined standards. All information pertinent to each criterion should also be collected systematically during the prequalification process prior to evaluating them against the required qualifications. This helps ensure that only those qualified bidders remain eligible after a detailed analysis has been conducted. Proper selection of winning bids based on these criteria will ensure the successful completion of any construction project.

Selection Of Winning Bids

The selection of a winning bid is the most important part of serial tendering in construction. This process involves evaluating all bids according to predetermined criteria and selecting one that meets these requirements. The bid evaluation criteria must be determined before the bidding stage, so bidders can understand what they need to provide in order to win the contract.

The bid selection process begins with an analysis of each bidder’s proposal to evaluate how closely it meets the criteria set out by the client. Bidders must also demonstrate their technical capabilities for performing the work as well as provide evidence of their financial stability. After reviewing all bids, a decision is made on which bidder best fulfills all of these requirements.

Once a decision has been reached, there are public procurement regulations that govern how contracts are awarded and negotiated between clients and contractors. It is important to follow these rules because failure to do so could result in costly disputes or legal action. Consequently, careful consideration should be given when selecting a winning bid during serial tendering in construction projects. Transitions into further discussions about public procurement regulations will now take place.

Public Procurement Regulations

A recent survey revealed that nearly 70% of construction projects in the United States use serial tendering as their procurement method. Serial tendering is a public procurement process that involves inviting contractors to submit sealed bids on specific project components, such as labour and materials. To ensure fairness and transparency during this process, all prospective bidders must adhere to certain public procurement regulations.

The following are some of the most important tender regulations:

- Eligibility Requirements: All potential bidders must meet certain criteria to be eligible for consideration by the procuring authority. This may include having a valid license or certification, providing financial statements, and meeting other qualifications set forth in the bid documents.

- Submittal Requirements: Bids must be submitted according to specified guidelines and timelines outlined in the Request For Proposal (RFP). This includes requirements related to format, content, language, signatures, deadlines, etc.

- Evaluation Criteria: The evaluation process should be detailed in the RFP so that all interested parties can better understand how they will be evaluated against competitors. Common criteria used when evaluating bids include price, quality of services/products offered, technical capabilities & experience of the personnel involved with project delivery, capacity for timely completion, and compliance with safety standards.

These regulations provide an effective framework for ensuring fair competition among all participants while helping procuring authorities make informed decisions about awarding contracts to qualified vendors who offer competitive prices without compromising quality or service. As a result, these regulations play an integral role in successful outcomes for both buyers and sellers alike within the construction industry.

With proper adherence to these rules from start to finish of any bidding process, it becomes easier for companies seeking contract opportunities while increasing confidence amongst those selecting them. Moving forward into the next section we discuss the documentation required when submitting a bid; something that needs careful attention prior to submission if you intend on being considered seriously by customers looking for goods or services provided through serial tendering processes within construction markets globally.

Documentation Required To Submit A Bid

Serial tendering in construction requires a specific set of documents to be submitted as part of the bid submission. Depending on the project, contractors must prepare bids that meet all the requirements outlined by the owner or public agency in charge of procurement regulations. In order to properly submit a bid for serial tenders, there are certain documentation requirements that need to be followed.

The first step in preparing a bid document is to review and understand any pre-bid instructions provided by the procuring entity. These instructions should include an outline of what types of documents are required and how they should be formatted. Once this information has been obtained, it’s important for bidders to ensure that their documents adhere to these guidelines when submitting their bids for serial tender projects.

Additionally, bidders must provide accurate estimates based on current market conditions along with evidence of their financial capability and experience in similar projects. This helps demonstrate their ability to successfully complete the job according to specifications and within budget constraints.

It is also important for bidders to pay close attention to details regarding deadlines for submission and payment terms; failure to do so could result in disqualification from consideration for winning the contract. Furthermore, bidders should be familiar with other common procedures associated with serial tendering such as site visits prior to bidding, post-bid negotiations, and dispute resolution methods if needed. By taking these steps into account during the preparation of their documentation, the successful completion of a serial tender becomes much more achievable.

Understanding all aspects related to the documentation required for effective bid submission can help prevent costly mistakes down the road when participating in serial tenders. It is essential that bidders take sufficient time before finalizing their submissions in order to avoid issues later on during project implementation due to poor preparation at the initial stages. Being mindful about following each step involved will ultimately increase chances for success in being awarded contracts through serial tendering processes in construction projects. Common mistakes made during participation in serial tenders come next.

Common Mistakes To Avoid When Participating In Serial Tenders

Irrationally, many bidders for serial tendering in construction projects fail to realize the importance of avoiding mistakes and reducing risks when submitting a bid. It may seem counterintuitive but taking proper precautions can make all the difference in whether your bid is accepted or rejected.

Firstly, it’s essential to familiarize yourself with the tender process itself before you actually submit bids. Doing so will help minimize errors from occurring through lack of knowledge. Additionally, having an understanding of how bid evaluation works can give you insight into what criteria are being assessed when awarding contracts. This information can then be used to tailor your proposal accordingly in order to increase its chances of success.

Another key factor to consider is ensuring that each stage of the tender process is completed accurately and on time. An incomplete or late submission could disqualify you from consideration altogether; therefore, it’s important not to overlook any details as they may have significant consequences further down the line. Finally, never assume that just because one part of your tender has been successful, it means that you automatically qualify for the remainder of the contract – there may still be other elements that require additional evidence or documentation.

Taking these steps can significantly reduce the risk associated with participating in serial tenders and assist you in meeting any contractual obligations set out by clients during the bidding process.

How To Calculate Risk When Submitting A Bid

When submitting a bid in serial tendering, it is essential to calculate the risk associated with that particular bid. This involves evaluating a variety of factors such as market conditions and competitive pricing strategies.

The following table outlines some key aspects to consider when assessing risk:

| Factors | Potential Risks |

|---|---|

| Market Conditions | Unforeseen changes in the marketplace could lead to unforeseen cost increases or unexpected competition for resources. |

| Competitive Pricing Strategies | Incorrectly estimating costs compared to competitors’ bids can cause an increase in expenses or reduce profits. |

| Environmental Regulations | Strict environmental regulations may be prohibitively expensive or difficult to comply with. |

| Labor Availability and Costs | Low availability of skilled labor at reasonable prices can limit production capacity or require additional training investments. |

| Supply Chain Issues | Inefficient supply chains can result in delays, higher costs, and decreased quality control. |

It’s important to remember that all risks should be considered before making any decisions on bidding strategy. These evaluations will help determine the potential financial implications if a bid is accepted and guide decision-making during negotiations. Additionally, they also provide insight into how much time needs to be allocated to researching potential solutions to overcome risks and challenges related to serial tendering projects.

Potential Solutions To Overcome Risks And Challenges

Moving on from calculating risk when submitting a bid, there are potential solutions to help overcome risks and challenges. Risk management strategies can be implemented to manage the uncertainty caused by factors such as competition for tenders or changes in regulations.

First, the tender risk assessment should be undertaken at each stage of the tendering process – before submitting a bid, during evaluation, and post-award. This helps identify any potential problems that could arise throughout the entire tendering cycle. Additionally, it allows organizations to assess the overall impact of their decision-making on the outcome of an individual tender or across multiple tenders over time.

Second, organizations should consider how they can optimize their bids through bid optimization techniques. These techniques involve analyzing data relating to past bids and market trends to improve bidding decisions and reduce losses due to miscalculations or poor planning. By understanding what has worked successfully in previous tenders and learning lessons from unsuccessful ones, organizations can gain insight into how best to approach future opportunities and minimize the risk associated with competing in construction tenders.

Finally, good communication is essential between all parties involved in the tendering process. Collaboration between stakeholders helps ensure that everyone understands their responsibility within the project timeline and the necessary steps taken toward the successful completion of work. Open dialogue also ensures that any issues arising throughout the course of work are addressed promptly and effectively:

- Developing robust systems for sharing information internally;

- Ensuring all staff members understand expectations around reporting requirements;

- Encouraging open communication between bidders and buyers;

- And establishing clear rules about data ownership rights prior to submission.

The above measures will help create favorable conditions for successful outcomes when it comes to serial tendering in construction projects. It’s important for organizations not only to calculate risk but also take proactive steps towards mitigating it so that they can compete more competitively in these circumstances while limiting financial exposure along with other forms of loss associated with participating in serial tendering processes.

Frequently Asked Questions

What Are The Best Practices For Serial Tendering?

Serial tendering is a complex process that can have long-reaching impacts on the success of a construction project. As such, it’s essential to understand best practices for serial tendering in order to ensure optimal outcomes. From tender selection strategies and bid optimization techniques to communication protocols between stakeholders, there are many ways to approach the tendering process with greater efficiency and effectiveness.

The first step towards successful serial tendering is understanding the importance of selecting the right bids. By carefully evaluating each potential contractor based on their qualifications, past projects, customer reviews, and other criteria, contractors can identify which vendor offers the most value for money as well as being reliable and trustworthy. Once a selection has been made, clear communication must be maintained throughout the entire duration of the contract – from initial negotiations through to completion of all works required. This will help keep everyone involved informed about any changes or updates needed during the course of construction.

In addition to these core best practices for serial tendering, it’s also important to consider how technology can facilitate better processes too. Automation tools like eTendering platforms enable faster response times when issuing invitations to tender (ITTs) and provide an easy way for bidders to submit their documents securely online while optimizing time spent managing responses. This type of tooling helps optimize bidding costs as well as improve overall workflow efficiency around the tendering process itself.

By leveraging these key elements including bid selection strategies, communications protocols, and automation tools, construction professionals can effectively manage their serial tendering efforts while achieving desired results more quickly than ever before. With careful consideration given at every stage of this vital part of any major building project, organizations can enjoy smoother operations with fewer hiccups along the way – making successful delivery far easier to achieve.

What Are The Differences Between Serial Tendering And Traditional Tendering?

Serial tendering and traditional tendering are two distinct methods of awarding contracts in construction. While both processes involve submitting bids for projects, the differences between them can have an important impact on a contractor’s success. This article will explore what distinguishes serial tendering from traditional tendering and why it is beneficial to understand these distinctions.

Traditional tendering involves contractors responding to requests for proposals (RFPs) with specific deliverables that must be met by an agreed-upon timeline. The lowest cost bidder typically wins the contract; however, there is no guarantee that they will also provide the highest quality workmanship or customer service. Serial tendering differs from this model in several ways, including its emphasis on quality over price and its focus on long-term relationships rather than short-term commitments.

One major difference between serial and traditional tendering is how bidding works: instead of selecting one firm to complete all aspects of the project, multiple firms may bid on different components within the same job. This allows for greater flexibility as well as improved competition among bidders since each component can receive multiple bids from various companies offering specialized solutions. Additionally, with serial tendering, consideration is given to factors such as speed, reliability, and customer service when determining awardees – not just price – making it easier for smaller businesses to compete against larger ones and win contracts they might otherwise miss out on due to their size alone.

In addition to heightened competition among bidders, serial tenders tend to develop longer-lasting partnerships between contractors and clients due to their emphasis on trustworthiness rather than low prices or quick turnaround times. Clients gain assurance that qualified contractors who specialize in certain areas are being utilized while also building confidence in their ability to meet deadlines without sacrificing quality standards along the way.

For contractors, this offers advantages beyond simply winning contracts; because they become more familiar with clients’ needs over time through regular contact throughout any job’s duration, future opportunities often arise for repeat business based upon established trust levels at earlier stages of engagement. Understanding the subtle yet significant differences between serial vs traditional tendering can help land successful jobs while setting up favorable conditions for potential further engagements down the line.

How Can I Ensure That My Bid Is Selected For A Serial Tendering Process?

When considering how to ensure that your bid is selected for a serial tendering process, there are some key considerations you should bear in mind. This article will explore three tips on preparing and submitting bids during the serial tendering process to help increase the chances of success.

Firstly, it’s important that you understand exactly what the tender requirements are before bidding. It’s essential to read through all documents associated with the bid process thoroughly, ensuring that all criteria set out by the client have been met. When crafting a response to any questions asked as part of your submission, be sure to use language which clearly demonstrates an understanding of their needs. Here are three things you can do:

- Make sure you have carefully read the invitation document

- Understand why they may need certain services or products

- Ensure any additional information requested is provided promptly.

Secondly, when submitting your bid make sure you provide accurate details and backup statements with evidence where necessary. Provide clear examples of previous work undertaken if applicable – this allows clients to gain confidence in your capabilities and helps them assess whether you’re best placed for the job. Additionally, pay attention to detail regarding deadlines – late submissions will not be accepted so plan ahead accordingly and allow yourself plenty of time! Some further advice includes:

- Demonstrate knowledge about what the project entails

- Present data which supports your claims

- Submit bids well before deadlines for maximum consideration.

Finally, remember that each stage of a serial tendering process requires separate assessment against different criteria; therefore it’s important that each response stands alone without relying on responses from prior stages. To give yourself the best chance at progressing successfully through each stage, consider providing comprehensive answers and tailor them specifically towards individual requirements set out by potential clients. The following points could also prove beneficial:

- Be specific in describing how you meet the required standards

- Showcase relevant experience within each response

- Tailor solutions based on client-specific criteria.

By taking into account these steps when preparing for a serial tendering process, bidders can put themselves in good stead for being successful throughout every stage involved in securing projects via this method.

Is There A Way To Minimize The Risk Associated With Serial Tendering?

Risk is an unavoidable part of the construction industry. Serial tendering in particular can be a minefield, rife with potential pitfalls and threats to a successful outcome. But there are ways to minimize this risk associated with serial tendering projects, without sacrificing quality or profitability.

One way to reduce the risk of a failed bid during serial tendering is by preparing thoroughly upfront. This means researching current market prices for materials and labour costs, as well as familiarizing yourself with any relevant regulations and compliance standards that could affect your project’s scope. Doing this will give you greater clarity about what kind of profit margin you need to make in order for the project to go ahead successfully. Here are some other ideas:

- Put together a realistic budget based on accurate data from previous similar jobs

- Make sure all bids contain enough detail so they can be properly assessed and compared

- Create contingencies in case something goes wrong during the process

Having these strategies in place prior to submitting your bid should help you feel more confident when it comes time to submit it – reducing stress levels while also giving you peace of mind that everything has been taken care of properly! By putting in the effort up-front, you’ll be able to sail through each stage of the serial tendering process with minimal risk involved. So don’t let fear stop you from taking advantage of this potentially lucrative opportunity; instead, take proactive steps toward minimizing the risks associated with serial tendering in construction today.

What Are The Most Common Mistakes That Contractors Make When Participating In Serial Tendering?

When participating in serial tendering, contractors must take care to avoid certain common mistakes. Serial tendering is a process that can involve multiple rounds of bidding and can be quite complex; therefore it is important for contractors to have knowledge of the risks associated with this type of construction contract. Understanding what mistakes are commonly made when engaging in serial tendering will help contractors minimize their risk while taking part in this process.

One mistake that many contractors make when undergoing serial tendering is not properly understanding the terms of the tender document before submitting a bid. It’s essential for each contractor to read all documentation thoroughly, including any amendments or addenda, as there may be changes from one round to the next which could affect how they should submit their bid. If clauses or conditions are misunderstood or misread, it could lead to misunderstandings later on down the line if awarded the project.

Another issue that often arises during serial tendering processes is miscalculating prices and costs. This can lead to a misunderstanding between both parties regarding budget expectations. Contractors need to ensure they understand all related expenses and factor them into their calculations when creating an accurate estimate for total costs and pricing before submitting bids throughout each stage of the tendering process. Failing to do so can create problems further down the road if cost overruns occur due to inaccurate estimates provided at earlier stages of bidding.

It’s critical for any contractor wanting to participate in serial tendering projects to understand these common errors so they can protect themselves from potential issues later on. Being aware of such pitfalls will enable them better prepare bids that accurately reflect their proposed solutions within budgetary requirements set out by prospective clients – ultimately helping increase chances of success through successful engagement in the serial tendering process.

Conclusion

Overall, serial tendering is a complex process that requires careful consideration and planning. It’s important to understand the differences between it and traditional tendering so you can make sure your bid stands out from the rest. By understanding best practices for serial tendering, minimizing risk, and avoiding common mistakes, contractors can increase their chances of success in this competitive environment.

It pays off to put extra effort into preparing for serial tendering – just like when we’re trying our luck at slot machines or playing online poker! If we pay attention to detail and strategize carefully, even if there are no guarantees of success, we’ll have an advantage over those who didn’t take the time to plan ahead.

The key takeaway here is that while nothing beats good preparation, taking risks can also be rewarding – especially when they’re well-calculated ones. With knowledge on our side and confidence in ourselves, success in serial tendering isn’t far away!

1 thought on “Master Guide 101: Serial Tendering In Construction”