In the construction sector, the Procurement systems are one of the popular terms used in any construction project. Anyhow, do you know what the major Procurement systems in the construction industry are? Before discussing further, it is vital to understand the definition of Procurement.

What is Procurement?

Procurement is the process of acquiring essential resources such as goods and services to the construction project. So, Proper procurement management leads to achieving project goals and objectives. Procurement includes the following components:

- Development of procurement strategy with new mechanisms

- Preparation of construction contracts

- Selection of eligible suppliers

- Management of the contracts and construction

And also, Procurement mainly covers the following three aspects.

- The Working arrangement (Procurement Systems)

- The tendering process or method of selection

- The form of contract to be used (FIDIC, JCT, ICE.. etc.)

What are the construction procurement systems?

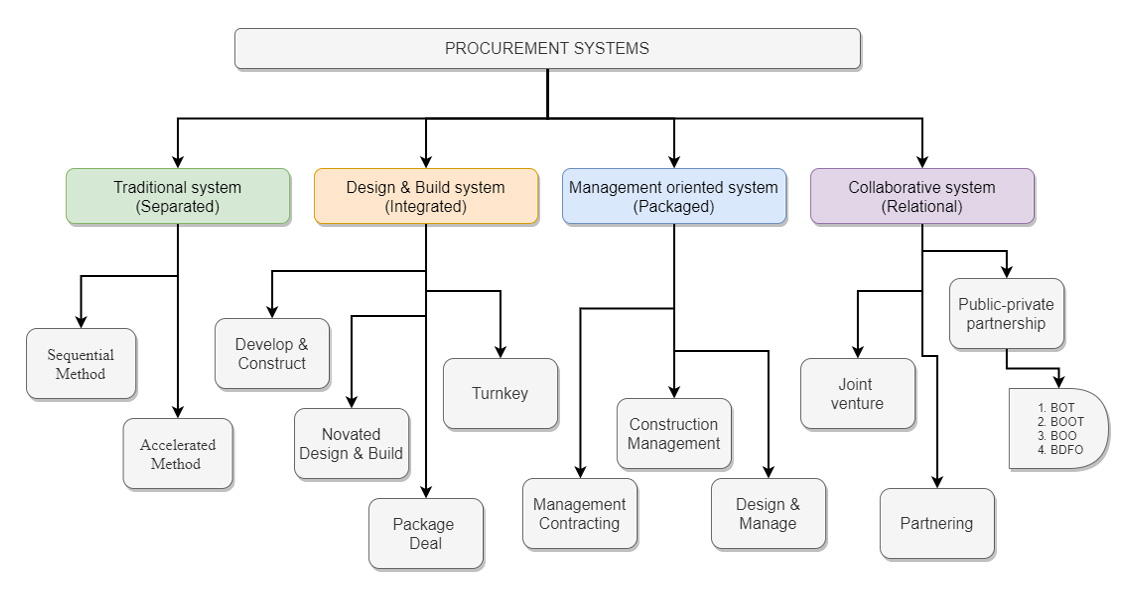

Four major procurement systems are exits in the construction. They are;

- Traditional system (Separated)

- Design and build system (Integrated)

- Management oriented system (Packaged)

- Collaborative system (Relational)

The different categories and sub-classification of construction procurement systems can be shown in the figure below.

Traditional Procurement Route

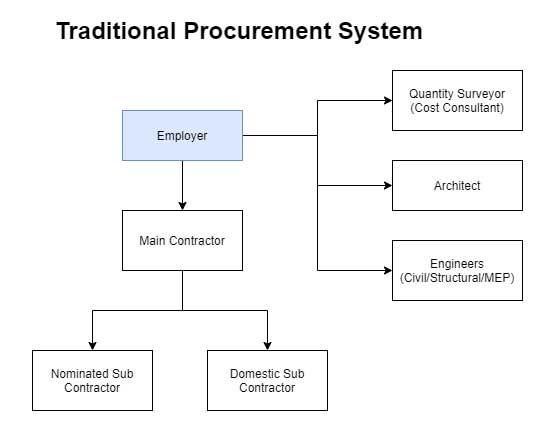

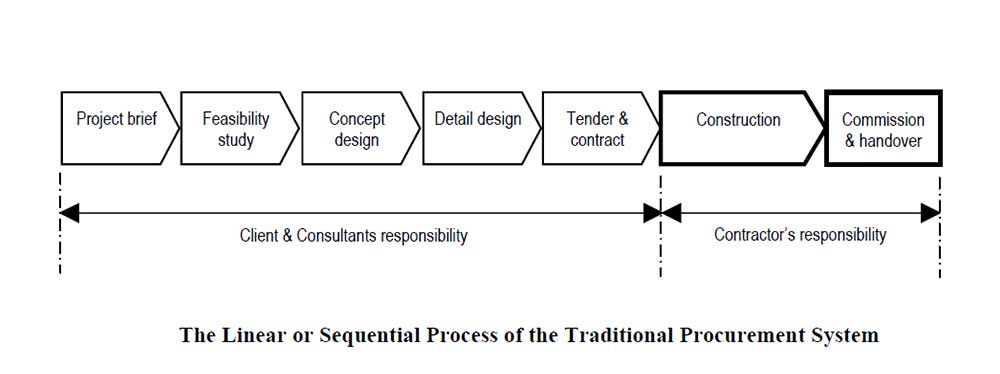

The traditional procurement method is called a design-bid-build or separated system. So, there is a rigid separation between the design phase and the construction phase. Indeed, in the design phase, all works are executed by the Employer, designer, and consultant. The Contractor involves in the construction phase, not to the design phase.

There are two variants in the traditional procurement system. They are,

- Sequential method

- Accelerated method

Process of the Traditional Procurement system

1. Sequential method

The client will be assigning a consultant team to act on their behalf. This team will produce the drawings, specifications, tender documents, and manage the tendering process, as well as selecting a contractor. Once the contract has been awarded, the contractor will be executing the construction based on the drawings and specifications made by the client’s consultant team.

2. Accelerated method

This method is a cutting-edge approach to expedite the choice of the Contractor and the start of the construction. It is based on the two-stage tendering or negotiated tendering processes. These involve conversations with a few chosen contractors (tenderers), submission of a fixed tender, and/or cost negotiations. This process provides an opportunity to exploit latest methods and introduce new technologies.

Advantages of Traditional System

- Most familiar method among construction stakeholders

- Leads to build architecturally sound projects

- Possibility of competitive tendering with detailed documentation

- Awareness of financial commitment before work began

- BOQs make for ease of valuation of variations as well as the high level of cost controlling and monitoring

Disadvantages of Traditional System

- Lack of integration and communication between parties because of the separation of design and construction phase.

- Minimum involvement of the Contractor to the design phase

- Since design and construction are done separately, it may add more time to the construction project.

- Difficulties in build-ability may occur due to the separation of design and construction.

- Parallel work is not possible.

Design and Build Procurement System

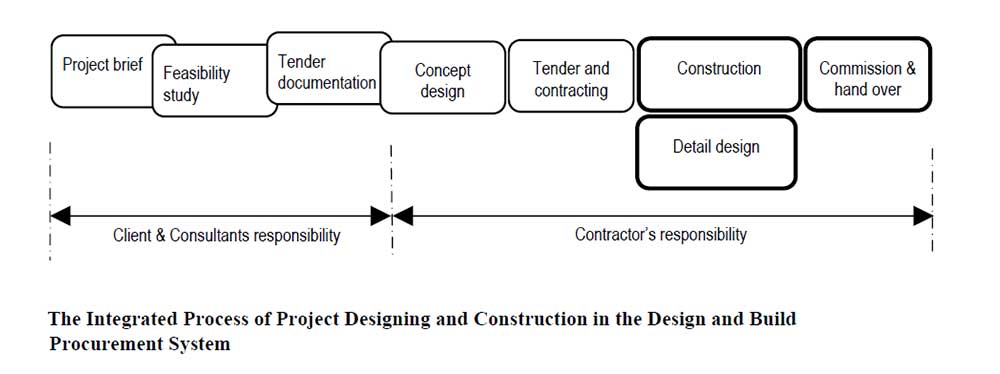

Design and build is known as an integrated system. It is also a great way to manage multiple tasks of the projects at once. In this procurement method, One Party (Contractor) shall do both design and construction phases. Thus, Designing and contracting both stages can be done parallel. As well as that, construction can start before all the detailed designs are completed. There is a single contract between the client and the Contractor, and the Contractor is responsible for design and construction. This system is usually done with a lump sum fixed-price basis.

There are four variants in the design and build system.

- Develop and construct

- Novated design and build

- Package deal

- Turnkey

1. Develop and Construct

Here, the client appoints designers to prepare concept design. After that, the Contractor develops the concept design. The Contractor produces detailed drawings, selected suitable materials, equipment, proposals with the bid. The Contractor is responsible for the design development only.

What is the difference between design and build and develop and construct?

- In Design and Build, the client issue the performance specification, quality control procedure and client brief, and evaluation criteria. Then, the Contractor does his design based on that information. So the client/his team does not have control of the design.

- Whereas in the Develop and Construct method, the client’s team issue, additionally the concept design and outline specification to the Contractor. So the client has control of the design.

2. Novated Design and Build

In this method, the client appoints consultants to prepare a conceptual design. Unlike develop and construct method, once the Contractor is selected, the client novates the responsibility of conceptual design to the Contractor. Novation means the Contractor takes all responsibility for design works that are carried out to date. Briefly, the Contractor is responsible for his design and the previous design also.

3. Package Deal

The Contractor offers a total complete ‘package’ to the client with designers, engineers, quantity surveyors, etc. The client can get comprehensive service from the Contractor. Because of this package system, design costs may be less as well as total project duration may reduce.

4. Turnkey

The turnkey is an American term for “all in” or package contract. The Contractor is responsible for the total project. The Contractor is liable for the design to handover over the keys of the project. Here the Contractor agrees to design, construction, supply and install equipment, provide furniture, train the client’s personnel, and after that the handing over the project to the client with the relevant facilities.

Advantages of the Integrated System

- Single point of responsibility.

- The overall project duration is less because of the integration.

- High level of build-ability because of the involvement of the Contractor to the design phase.

- The client’s financial risk is minimum.

- Design changes may be minimum due to early collaboration between the Contractor and designers. Therefore total project cost may be reduced.

- A better option for inexperienced clients

Disadvantages of the Integrated System

- Difficulties in bid comparison

- There is a lower level of completion at the bidding process than other systems.

- Variation management is difficult.

- Best proposals may not be visible.

- The bidding process can be expensive for bidders.

- High level of risks to the Contractor

Management Oriented Procurement systems

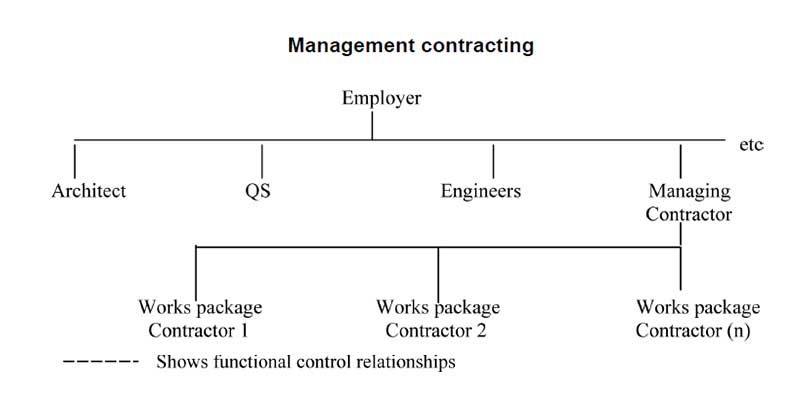

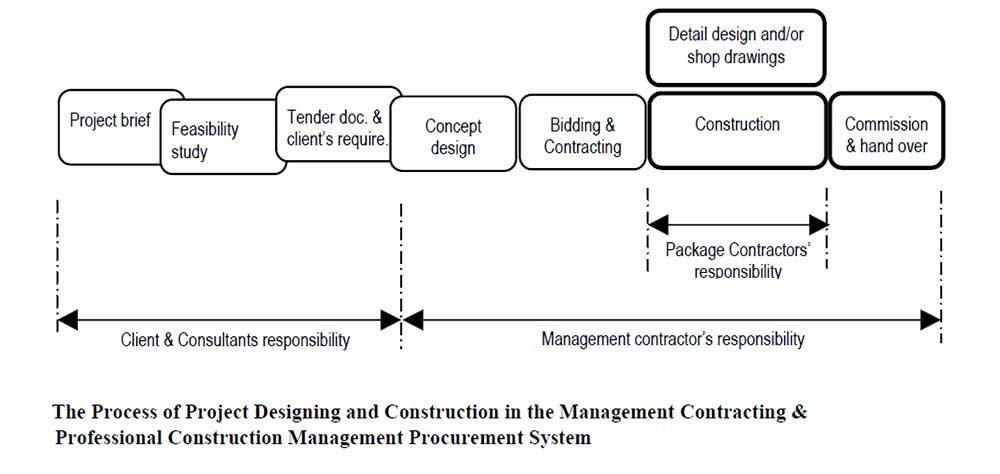

In the management contacting method, an appointed contractor manages the contact works as a manager on behalf of the client. Hence, This appointed Contractor is responsible for management and coordination if design and construction work.

This appointed Contractor has more expertise to manage the design and construction of a project. There are three common variants of the management-oriented route. They are;

- Management contracting

- Construction management

- Design and manage

1. Management contracting

The essential feature of this system is management contractor does not do any construction work himself. But the management contractor is providing professional management service to the client. This system allows increasing build-ability as well as there is a high degree of flexibility in the design process. This method consists of sub-contracting.

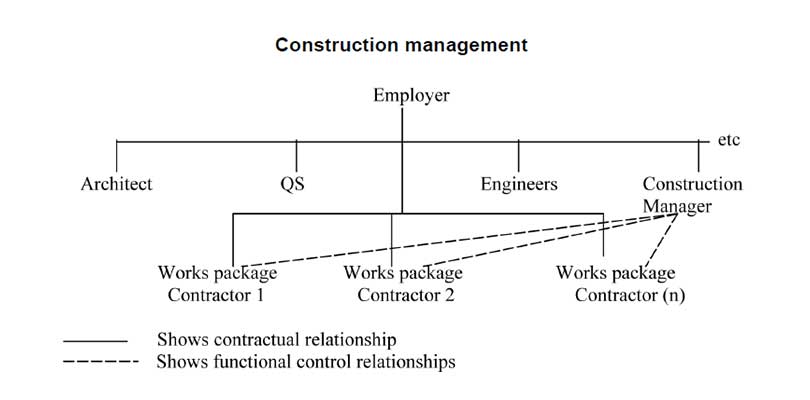

2. Construction management

The client appoints a construction manager to provide a service for design and construction. This method is based on a simple consultancy concept. There is close integration with management. There are many contractors (package contractors) who are responsible for defined work packages.

To conclude, in the two contracting methods – management contracting and construction management contracting – the contractors are paid to manage, acquire, and oversee the building of a project. A number of packages or specialist contractors need to outsource the actual construction work. This means that the Contractor is employed as a construction advisor and is part of the Employer’s team.

What is the main difference between contract management and construction management?

- Management contracting involves a contractual arrangement between the package contractors and the management contractor.

- Construction management, on the other hand, is a situation in which specialist sub-contractors or package contractors enter into an agreement with the Employer. This method of contracting allows for a direct relationship between the Employer and the sub-contractors.

Who is responsible for the delay in the Management contract?

- In the Management contact procurement method, the client has a contractual link with the Management contractor (MC) only. So the contractual risk is taken by the MC. Therefore, he has responsibility for any contractual delay.

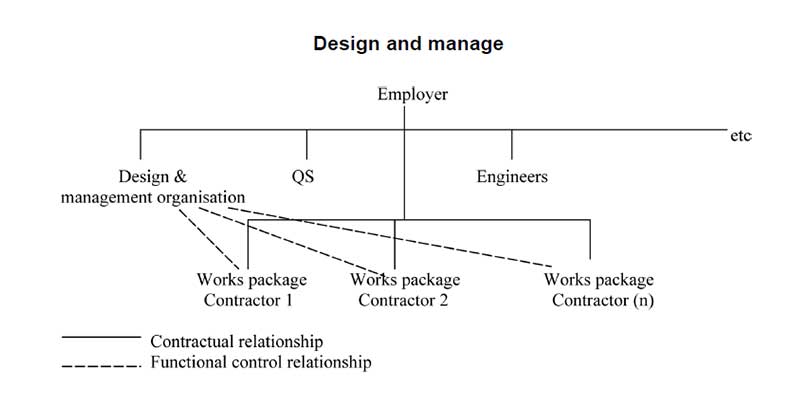

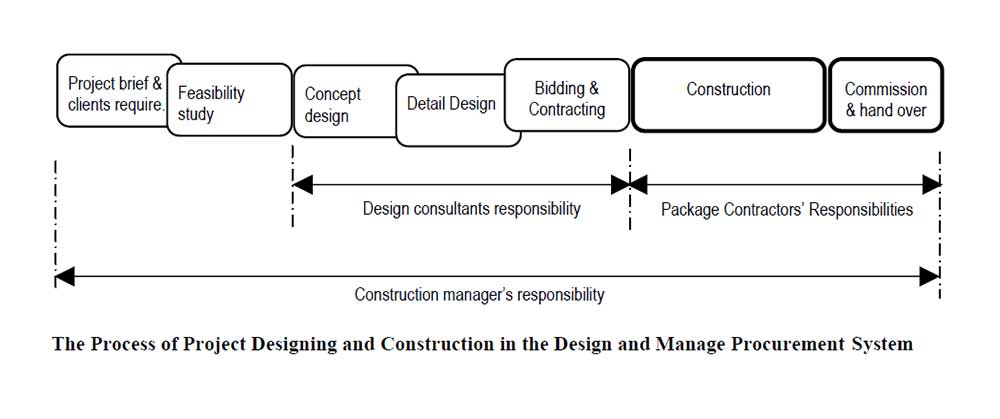

3. Design and manage

This method involves hiring a single organization to design and manage a construction project. They complete the work themselves, but with the assistance of specialist sub-contractors or package contractors. All package contractors must enter into a contract with the Employer. Additionally, a design and manage contracting firm or company is brought in as a consultant for the Employer and becomes part of the project team. In this way, the project is designed, managed and constructed to the highest standards.

What is the difference between Design & Build and Design & Manage?

- In design and build procurement method, the client appoints a Design & Build Contractor to carry out the designing and constructing works both.

- So the client has a single-point responsibility.

- In the design and manage path, the client appoints a Design & Manage Contractor, and first, he will do the design, and then the project will be split into several packages and finalize the packages.

- Then the client enters into contracts with package contractors, and the Design & Manage contractor will manage the package contractors after it is similar to the construction management procurement method.

- So in this method, the client has contracts with several package contractors. So the client does not have single-point responsibility.

Advantages of The Management Oriented System

- Suitable for a complex and broad-scale project.

- Flexibility in changes.

- An early start to the construction works.

- Less project duration.

- It is a better option for inexperienced clients.

Disadvantages of The Management Oriented System

- An extra layer of management will occur extra expensive.

- The involvement of more number of professionals may lead to occur conflicts.

- It is Less familiarity due to less popularity of this system.

Collaborative Procurement systems

The essential feature of this collaborative procurement method is a collaboration between two or more parties. And also, they are delivering the construction project more efficiently by sharing power and investments. In this procurement method, there is financial sharing as well as risk-sharing between parties. Financial risk is to the client in other procurement systems, but in a collaborative system, the risk is sharing between parties. There are various types of procurement systems under the collaborative procurement route. They are;

- Joint venture

- Partnering

- Public-private partnership (PPP)

1. Joint venture

A collaborative agreement between two or more parties to fulfil the goals of construction projects by sharing risks and resources.

2. Partnering

Partnering is an arrangement, which tries to create an effective management process between two or more organizations. This method allows for a win-win scenario for all parties. Because of that, there will be a reduction in disputes.

Partnering can be used with any type of procurement system.

What is the best procurement route to adopt partnering?

I believe the Traditional route is the best procurement path suitable to adopt partnering. Because in the traditional path, pre-contract and post-contract stage are separated. So there is a possibility of more conflicts. Thus, by adopting partnering, those conflicts can be minimized.

3. Public-private partnership (PPP)

Public-private partnership is a long term legally binding agreement between government (public) authority and a group of private sectors. It is to design, finance, construct, manage, maintain, and operate a public project.

Private finance initiative (PFI) is a common form of private-public partnership (PPP).

PFI is a procurement route where the private sector bears all expenses of public projects and gives more efficient service to the public. Here the private sector provides services on a long term basis. Through a concession agreement, the government gives certain rights to private party build and operate the project for a specified period of time. In this period of operation, the general public can get the service of the project, as well as the private party, can earn their expenses of the project with profit.

The private sector will do maintenance works also during this operation period. Typically the concession period is between 5 to 50 years. At the end of the concession period, the private party has to hand over the project to the host government.

Under the Private Finance Initiative method, there are few variants. Such as,

- BOT – build, operate, and transfer

- BOOT – build, own, operate, and transfer

- BOO – build, own, operate

- DBFO – design, build, finance, and operate

Advantages of Collaborative systems

- Technology transfer

- The risk is sharing between parties.

- Increased build-ability

- A better option for developing country

- Suitable for a large and complex project

- Individual commitment toward the project is high.

- Possibility to get better quality construction project at the end

Disadvantages of Collaborative systems

- Always may not profitable.

- Since there are a lot of parties are involved in the project, it will be difficult when managing relationships with each party.

2 thoughts on “4 Prominent Procurement Systems in Construction Easy Guide”