Are you ready to dive into the world of curtain wall systems?

Get ready for an ultimate guide that will take you on a journey through the history, types of curtain walling, benefits, and different materials of these innovative structures.

We’ll walk you through the design considerations, and installation process, and even share tips on maintenance and cleaning.

Plus, we’ll give you a sneak peek into future trends in curtain wall technology.

So buckle up and prepare to become a curtain wall expert!

Key Takeaways

- Curtain walls have a long history, dating back to ancient civilizations, and have evolved with advancements in technology and design.

- Three primary types of curtain walling systems are “stick systems,” “unitized systems,” and “bolt-fixed glazing.”

- Modern curtain walls offer benefits such as enhanced natural light, energy efficiency, versatility in design, and noise reduction.

- Different types of materials, such as aluminum, glass, steel, stone, or concrete panels, can be used for curtain walls depending on aesthetics, performance, and budget considerations.

- Design considerations for curtain walls include building orientation, energy efficiency requirements, aesthetic preferences, structural integrity, and consultation with structural engineers.

The History of Curtain Walls

The history of curtain walls dates back to ancient civilizations, where they were used for both practical and aesthetic purposes. In fact, the concept of curtain walling can be traced all the way back to the Egyptians and Romans. They used this architectural technique to enclose their buildings with a non-structural outer layer made of materials like stone or glass. This innovation allowed them to create large, open spaces within their structures while still providing protection from the elements.

Curtain walls continued to evolve throughout history, with advancements in technology and design. During the Industrial Revolution, iron and steel became popular choices for constructing curtain walls due to their strength and durability. The use of glass also became more prevalent, allowing for greater natural light penetration into buildings.

In modern times, curtain walls have become an integral part of contemporary architecture. With advancements in materials like aluminum framing systems and energy-efficient glazing options, architects now have more flexibility in creating visually stunning facades that are also sustainable and functional.

Today’s curtain walls not only provide structural support but also offer insulation against heat loss or gain and noise reduction. They can even incorporate features such as solar panels or shading devices for enhanced energy efficiency.

Overall, the history of curtain walls showcases how this architectural element has evolved over time to meet various needs – from protection against external forces to creating aesthetically pleasing designs that enhance our built environment.

What is a Glass Curtain Wall System?

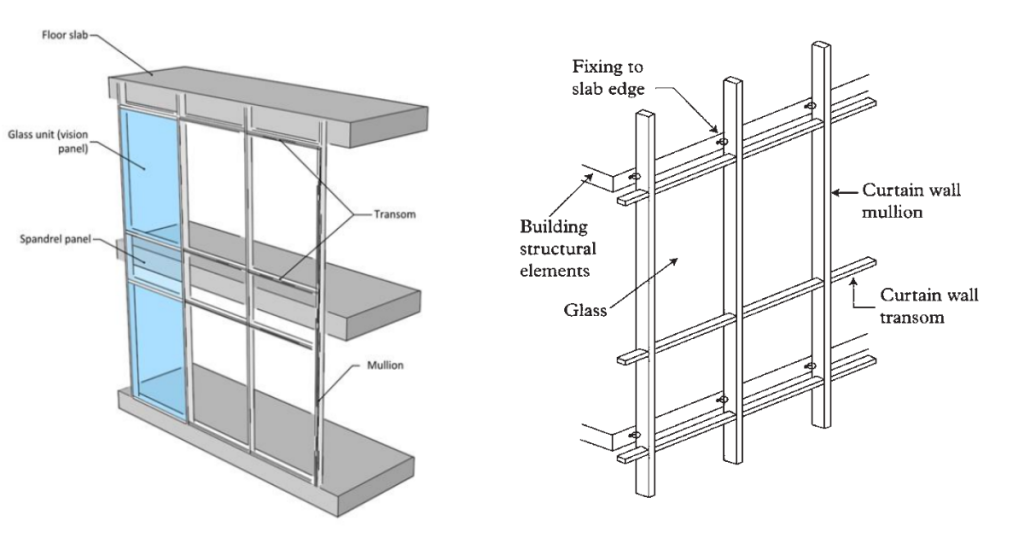

A “curtain wall” is an external building feature that shields occupants and the structure from external environmental impacts. It not only provides protection from elements like wind and rain but also offers various design and functional possibilities. Curtain walls can be entirely glass or incorporate materials like stone and aluminum panels.

They may feature architectural elements for aesthetic enhancement or environmental management, such as brise soleil for shading or photovoltaic panels for electricity generation. Unlike structural components, modern curtain walls are designed as cladding elements, ensuring their failure won’t cause disproportionate damage to the building.

Types of Curtain Walling

Three primary types of curtain walling systems are

- stick systems

- unitized systems

- bolt-fixed glazing

Stick Systems

These systems vary in design aesthetics, construction methods, and overall design. While each system meets building design load requirements, they respond differently when subjected to blast loads, potentially offering varying levels of occupant protection. Hence, understanding these diverse systems is crucial for their effective use.

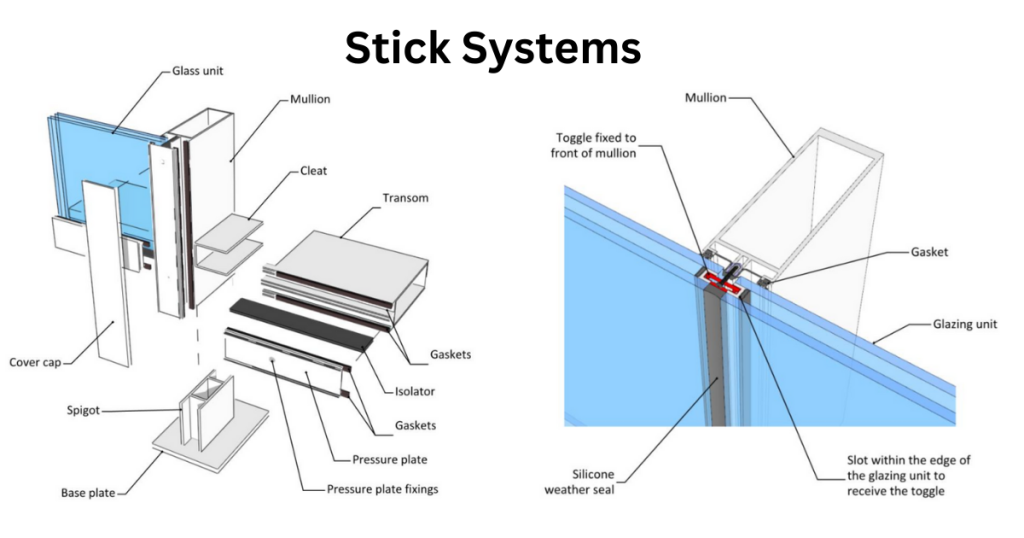

Stick systems for curtain walls consist of individual vertical mullions and horizontal transoms, also known as “sticks.” These elements are connected to the building’s floor slabs, with large glass panels for external views and opaque spandrel panels to conceal the structural framework. Mullions and transoms are typically made from extruded aluminum sections and come in various sizes, colors, and finishes. They are joined using angles, cleats, toggles, or locating pins, with different options available for varying load capacities to achieve the desired design.

The dimensions of these sections are determined by factors such as the horizontal span between mullions, the height between floor slabs, environmental forces like wind, and the weight of the glass. The glass is usually supplied by a separate glass manufacturer and is designed to be compatible with the system.

In stick systems, the components are often pre-fabricated in a factory, cut to the required lengths, and prepared for assembly. A team of specialist contractors then installs these elements on-site. Once the mullion and transom grid are in place, glass panes and spandrel panels are positioned and secured using pressure plates, which are concealed by cover caps. Another method, toggle glazing, clamps the glass internally via a channel.

Stick systems are favored for their versatility and cost-effectiveness, making them a common choice for applications like shopping centers and low-rise office buildings.

Unitized Systems

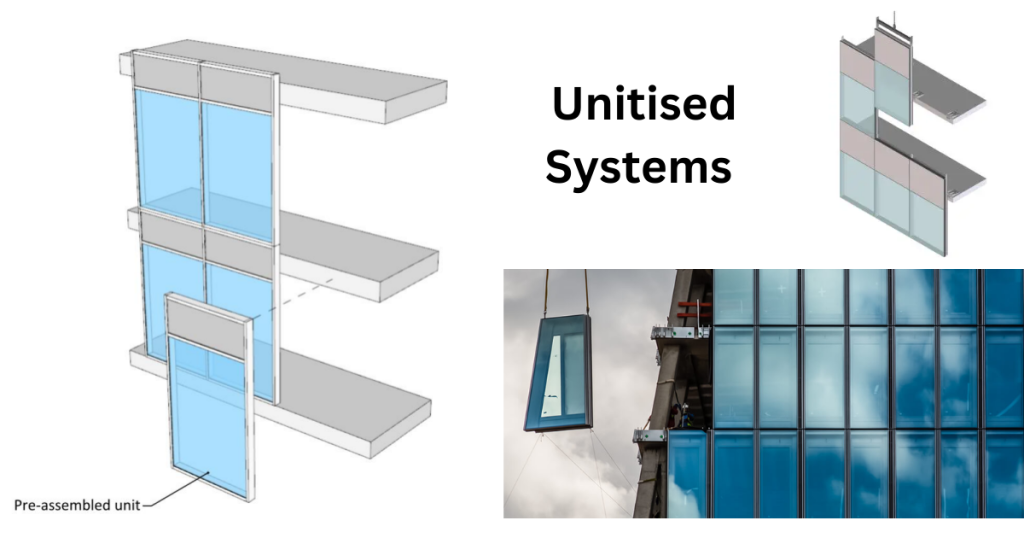

A unitized system takes the component parts of the stick system and assembles them into individual prefabricated units within a factory setting. These units are then transported to the construction site and fixed to the building’s structure.

Factory preparation of unitized systems allows for more intricate designs and the use of materials that demand strict quality control to achieve a high-quality finish. This approach also enhances precision and reduces the number of on-site joints, resulting in better air and water tightness compared to stick systems.

One of the primary advantages of unitized systems is their rapid installation. When compared to stick systems, these factory-assembled systems can be installed in just one-third of the time. Unitized systems are particularly well-suited for buildings that require a large amount of cladding and where access or site labor costs are high, such as high-rise buildings in cities like London and New York.

Within the unitized curtain wall systems family, some sub-categories benefit from speedy installation and a shift of labor costs from the construction site to the factory floor. These sub-categories include:

- Panellised Curtain Walling: This approach uses large prefabricated glazed panels that typically span between structural columns (often 6-9 meters) and are one storey in height. These panels are connected back to structural columns or floor slabs, similar to the unitized system. Due to their size, these panels often consist of discrete structural steel frames with glass panes fixed within them.

- Spandrel Ribbon Glazing: In ribbon glazing, spandrel panels are linked together to form long panel lengths, which are then delivered and installed on-site. Spandrels are the panels in a facade located between the vision areas of windows, often made of glass with opaque interlayers or painted to conceal the structure. They can also be constructed from other materials, including GFRC (glass fiber reinforced concrete), terracotta, or aluminum with insulation situated behind them.

Bolt-fixed Glazing

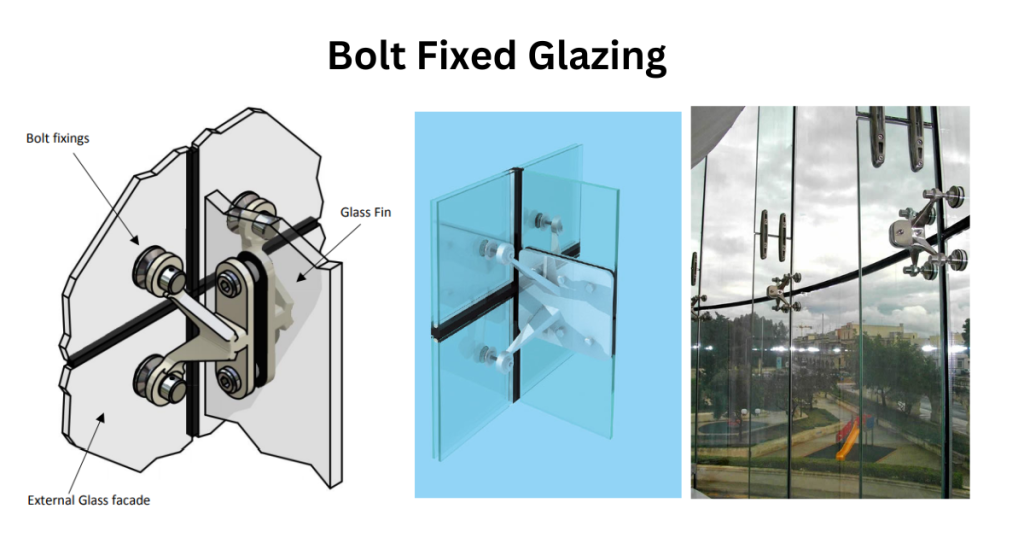

Bolt-fixed or ‘Planar’ glazing is typically used to cover specific areas in a building that architects or clients want to highlight, such as entrance lobbies, main atriums, scenic lift enclosures, or shop fronts. Instead of using frames on all four sides, like aluminum mullions and transoms, this approach supports glass panels with bolts, typically at the corners or along the edges of the glass. These bolt fixings are highly engineered components capable of spanning significant glass panes between support points.

The glass panels are delivered to the construction site with pre-drilled holes and stainless steel bolt fittings. The system is then assembled on-site. Different types of glazing used in traditional curtain walls, such as toughened, insulated, or laminated glass, can also be applied in bolt-fixed glazing if the manufacturer has the necessary skills and technology. Annealed glass is not suitable for bolt-fixed glazing because it lacks the required strength, and the glass thickness is typically greater due to the minimal support points.

The fixings that attach through the holes in bolt-fixed glazing are designed to allow for relative movement between the glass and the building structure. This movement can be caused by settlement, live loads, or thermal expansion and contraction. Bolt-fixed glazing needs a structural frame for support, which can be in the form of steel trusses, glass fins, or stainless steel tension systems. Given the critical role of the glass in these systems, risk assessments are crucial to ensure that the failure of one glass panel doesn’t lead to the progressive collapse of the entire structure.

Once installed, bolt-fixed systems are typically weatherproofed by applying a silicone weather seal between adjacent glass panels. These systems are available in various forms, ranging from complete solutions where the glass and fittings come from a single source to products designed by a structural engineer and sourced as individual components. When sourcing bolt-fixed glazing components separately, it’s essential that the system is evaluated and coordinated by a qualified contractor or engineer to ensure its integrity and functionality.

Doors Within Glass Facade

In each of the three curtain walling systems, the inclusion of doors within the façade is necessary. These doors are typically constructed from a single pane of glass and can come in various configurations, such as single-leaf, double-leaf, or turnstile. The doors are affixed to a supporting frame, which, in turn, is directly fixed to the building structure, with the façade integrated around them.

The door leafs themselves can either be framed, meaning they are supported on all four sides by a metal frame around the door leaf, or unframed, where the glass edges are exposed.

In the event of a blast, it is anticipated that doors within a glass façade will be the most vulnerable element and may fail first. While measures to strengthen these doors can be implemented, a more practical approach may involve reducing how far the doors extend into the internal space.

Additional guidance on mitigation measures for doors within facades can be found on the CPNI website.

Benefits of Curtain Wall Systems

You’ll love the benefits of using curtain wall systems. They offer a range of advantages that can enhance both the aesthetics and functionality of your building. Here are some reasons why curtain walls are worth considering:

- Enhanced natural light: With large glass panels, curtain wall systems allow ample sunlight to enter your space, creating a bright and inviting environment.

- Energy efficiency: Curtain walls are designed to provide excellent thermal insulation, reducing energy consumption and lowering heating and cooling costs.

- Versatility in design: Curtain walls offer endless design possibilities. You can choose from various materials, colors, and finishes to create a unique look that matches your vision.

- Noise reduction: By incorporating acoustic glazing options, curtain walls can help minimize external noise pollution, providing a quieter interior environment.

With these benefits in mind, it’s time to explore the different types of curtain wall materials. Each material has its own set of characteristics and advantages that will influence the overall performance and appearance of your building’s exterior. So let’s dive into the next section to learn more about them!

Different Types of Curtain Wall Materials

Take a moment to explore the various types of materials available for your curtain wall, each with its own unique characteristics and advantages.

Aluminum is one popular choice due to its lightweight nature and strength. It is also highly resistant to corrosion, making it a durable option for exterior applications.

Another material to consider is glass, which provides transparency and allows natural light to enter the building while creating a modern and sleek aesthetic. Glass can be customized with different coatings or tints to enhance energy efficiency or privacy.

If you are looking for a more sustainable option, consider using steel as your curtain wall material. Steel offers excellent structural integrity and can withstand extreme weather conditions. It is also recyclable, reducing its environmental impact.

Lastly, stone or concrete panels provide a timeless and elegant look for your curtain wall system. These materials offer durability and require minimal maintenance over time.

Ultimately, the choice of material will depend on factors such as aesthetics, performance requirements, and budget considerations when designing your curtain wall system.

Design Considerations for Curtain Walls

When considering the design of your curtain walls, it’s important to take into account factors such as building orientation, energy efficiency requirements, and aesthetic preferences. By paying attention to these aspects, you can create a curtain wall system that not only enhances the overall appearance of your building but also provides optimal functionality.

To help you visualize the key considerations for designing your curtain walls, here are some important factors to keep in mind:

- Building Orientation: Consider how sunlight will interact with your building throughout the day. Will certain areas receive more direct sunlight? This will affect the choice of glazing materials and shading devices.

- Energy Efficiency Requirements: Think about ways to maximize energy efficiency. Incorporate high-performance glass that reduces heat transfer and minimizes solar gain. Consider using insulated spandrel panels or thermal breaks between framing members.

- Aesthetic Preferences: Determine the desired look and feel of your curtain walls. Do you want a sleek and modern appearance or something more traditional? Consider different finishes, colors, textures, and patterns that align with your overall architectural vision.

- Structural Integrity: Ensure that the curtain wall system is designed to withstand wind loads, seismic activity, temperature fluctuations, and other environmental factors. Consult with structural engineers to ensure safety and durability.

Installation Process of Curtain Wall Systems

To ensure a successful installation of your curtain wall, it’s important to carefully plan and execute the assembly process. First, gather all the necessary tools and materials, including the curtain wall panels, anchors, brackets, sealants, and fasteners.

Next, properly prepare the building structure by cleaning and leveling it. Remove any existing moisture or debris to create a smooth surface for installation.

Once the building structure is prepared, begin by installing the anchor brackets according to the manufacturer’s instructions. These brackets will serve as the support system for your curtain wall panels. Take care to align each bracket precisely for proper alignment of all components.

Next, attach the curtain wall panels onto the anchor brackets using fasteners or clips provided by the manufacturer. Make sure to securely fasten each panel in place while maintaining an even spacing between them.

After installing all the curtain wall panels, thoroughly inspect for any gaps or misalignments. Use a sealant to fill in any gaps and create a watertight barrier between each panel.

In conclusion, proper planning and careful execution are crucial for the successful installation of curtain walls. By following these steps diligently, you can ensure that your curtain wall system is installed correctly and functions effectively.

This leads us into our next section about the maintenance and cleaning of curtain walls…

Maintenance and Cleaning of Curtain Walls

Make sure you regularly clean and inspect your curtain wall panels to maintain their appearance and functionality. Here are some important tips to keep in mind:

- Remove dirt and debris: Use a soft brush or cloth to gently remove any dirt or debris that has accumulated on the surface of the panels. This will help prevent staining and ensure that the panels look their best.

- Check for cracks or damage: Inspect the panels closely for any cracks, chips, or other types of damage. If you notice any issues, it’s important to address them promptly to prevent further deterioration and potential water leakage.

- Clean with mild detergent: To clean the panels more thoroughly, mix a mild detergent with water and use a soft cloth or sponge to gently scrub away stubborn stains. Avoid using harsh chemicals or abrasive materials that could cause damage.

- Rinse with water: After cleaning, rinse the panels with clean water to remove any residue from the detergent. This will help restore their shine and ensure that no cleaning agents are left behind.

Regular maintenance and cleaning of your curtain wall panels will not only keep them looking great but also extend their lifespan.

In the next section, we will explore future trends in curtain wall technology.

Future Trends in Curtain Wall Technology

There’s a lot of excitement about the future of curtain wall technology and the innovative advancements that are being made. As you look ahead, you can expect to see several trends shaping the future of curtain walls.

One major trend is the integration of sustainable features into curtain wall systems. With growing environmental concerns, architects and designers are striving to create more eco-friendly buildings. Curtain walls that incorporate energy-efficient materials, such as solar panels or photovoltaic glass, will become increasingly common. These advancements not only reduce energy consumption but also contribute to a greener and more sustainable future.

Another exciting development is the use of smart technology in curtain walls. Imagine having control over the transparency and shading levels of your building’s facade with just a touch on your smartphone. Smart glass technologies are being developed to allow for adjustable opacity, providing privacy when needed while allowing natural light to flood in when desired.

Additionally, there is ongoing research into improving the performance and durability of curtain wall systems. New materials and manufacturing techniques will enhance their resistance to extreme weather conditions such as hurricanes or earthquakes.

Frequently Asked Questions

What Are the Key Factors to Consider When Selecting a Curtain Wall System for a Specific Building Project?

When selecting a curtain wall system for your building project, consider factors like the building’s location, climate conditions, desired aesthetics, energy efficiency requirements, and budget constraints. These will help you make an informed decision.

Can Curtain Wall Systems Be Installed on Existing Buildings, or Are They Only Suitable for New Construction?

Yes, curtain wall systems can be installed on existing buildings. They are not only suitable for new construction but also offer a great option to enhance the aesthetics and energy efficiency of older structures.

Are Curtain Walls Only Used for Commercial Buildings, or Can They Also Be Used in Residential Projects?

Curtain walls are not limited to commercial buildings; they can also be used in residential projects. They provide an aesthetic and functional solution for large glass facades, allowing natural light and offering energy efficiency.

How Do Curtain Wall Systems Contribute to Energy Efficiency and Sustainability in Buildings?

Curtain wall systems can significantly improve energy efficiency in buildings. For example, they can reduce heating and cooling costs by up to 30%. This makes them a sustainable choice for both commercial and residential projects.

Are There Any Specific Building Code Requirements or Regulations That Need to Be Considered When Installing Curtain Wall Systems?

When installing curtain wall systems, you need to consider specific building code requirements and regulations. These ensure that the installation meets safety standards and addresses factors like fire resistance, wind load capacity, and structural integrity.

Conclusion

So now you have all the information you need to make a decision about curtain wall systems. You’ve learned about their history, the benefits they provide, and the different types of materials available.

You’ve also gained insight into design considerations, installation processes, and maintenance requirements.

With this knowledge in hand, you can confidently choose the right curtain wall system for your project.

So go ahead and embrace the future trends in curtain wall technology, and create a stunning architectural masterpiece that will stand tall for years to come!