Rebar, a fundamental component of concrete structures, plays a crucial role in reinforcing and enhancing their strength. This comprehensive guide aims to provide an objective and impersonal examination of rebar.

By exploring its definition, historical significance, various types, shapes, and codes, readers will gain a thorough understanding of this essential construction material.

Additionally, the guide will delve into the intricate world of rebar meshes and cutting machines, shedding light on the complexities of their usage.

Ultimately, this exploration will allow for a deeper appreciation of the importance of rebar within the realm of concrete structures.

Key Takeaways

- Rebar plays a crucial role in enhancing the tensile strength and durability of concrete structures.

- The selection of the appropriate type of rebar, such as deformed bars, epoxy-coated rebars, or stainless steel rebars, depends on the specific project requirements and environmental factors.

- Rebar helps prevent cracks and structural failures, improves stability and load-bearing capacity, and minimizes the effects of temperature changes, shrinkage, and expansion.

- Understanding the different shapes and shape codes of rebar is important for design, calculating the weight, and installation purposes.

Definition of rebar

A rebar, also known as a reinforcing bar, is a steel rod or mesh that is commonly used in construction to provide reinforcement and enhance the tensile strength of concrete structures. It plays a crucial role in ensuring the structural integrity and durability of reinforced concrete elements.

The use of rebar helps to distribute and transfer loads throughout the structure, reducing the risk of cracks or failure due to tension forces. By adding strength to concrete, rebar allows for the construction of larger and more complex structures that can withstand greater loads.

The size and spacing of rebar are determined by engineering calculations based on factors such as anticipated loadings, environmental conditions, and design requirements. Proper installation techniques are essential to ensure that rebar is positioned correctly within the concrete element for optimal performance.

Brief history and evolution of rebar usage

Throughout the centuries, the utilization of steel reinforcements in construction has undergone a significant evolution, resulting in improved structural integrity and durability.

The concept of reinforcing materials can be traced back to ancient civilizations such as the Egyptians and Romans who used stones, clay bricks, or wooden beams to strengthen their structures.

However, it was not until the 19th century that more advanced methods were developed. In the mid-1800s, iron rods began to be used as reinforcement in concrete structures. This was later replaced by steel rebars due to their superior strength and corrosion resistance.

With advancements in manufacturing processes and engineering techniques, rebar designs have evolved over time to meet specific project requirements. Modern construction practices now incorporate various types of rebar including deformed bars and epoxy-coated rebars for enhanced bond strength and longevity.

Overall, the history of rebar usage showcases a continuous strive towards improving construction methods and achieving safer and more durable structures.

Types of Rebar

Different types of rebar, such as deformed bars and epoxy-coated rebars, are commonly used in modern construction practices to enhance bond strength and increase the longevity of concrete structures. These different types provide specific advantages that make them suitable for various applications.

The following list highlights the key characteristics of different types of rebar:

- Deformed bars: These bars have ridges or deformations on their surface, which increase the mechanical anchoring between the bar and the surrounding concrete, improving bond strength.

- Epoxy-coated rebars: These rebars are coated with an epoxy layer to protect against corrosion and enhance durability in aggressive environments.

- Stainless steel rebars: With their high resistance to corrosion, stainless steel rebars are used in structures exposed to severe conditions like coastal areas.

Understanding the different types of rebar is crucial for selecting the appropriate option based on project requirements, environmental factors, and desired performance levels. This knowledge will further highlight the role and importance of rebar in concrete structures.

Role and Importance of Rebar in Concrete Structures

Concrete structures rely on the reinforcement provided by various types of steel bars to enhance their strength, durability, and resistance to external forces and environmental conditions.

Rebar, short for reinforcing bar, plays a crucial role in concrete construction by adding tensile strength to counteract the weak tensile properties of concrete. This reinforcement helps prevent cracks and structural failures caused by bending or stretching forces.

By distributing loads more evenly throughout the structure, rebar improves its overall stability and load-bearing capacity. Additionally, rebar enhances the durability of concrete structures by minimizing the effects of temperature changes, shrinkage, and expansion due to moisture variations.

The use of rebar allows for longer-lasting concrete constructions that can withstand harsh weather conditions and heavy loads while maintaining their structural integrity over time.

Read More: Ready-Mix Concrete Types I Mixing Ballast Concrete Ratio

Rebar Shapes and Shape Codes

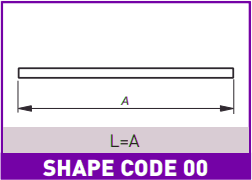

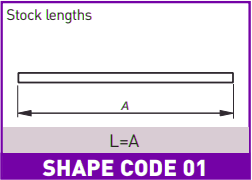

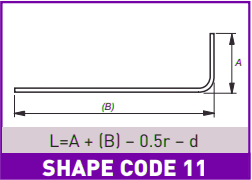

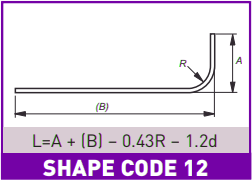

Reinforcement shape codes to BS8666:2005 are as follows.

| BS Shape Code | Shape | Formula |

|---|---|---|

| Shape Code 00 |  |

L=A |

| Shape Code 01 |  |

L=A |

| Shape Code 11 |  |

L=A + (B) – 0.5r – d |

| Shape Code 12 |  |

L=A + (B) – 0.5r – d |

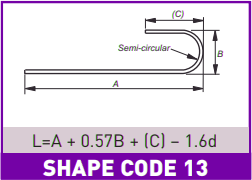

| Shape Code 13 |  |

L=A + 0.57B + (C) – 1.6d |

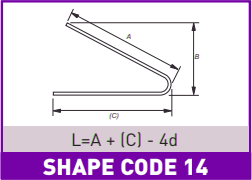

| Shape Code 14 |  |

L=A + (C) – 4d |

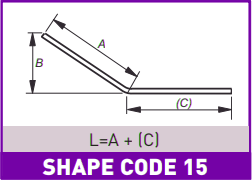

| Shape Code 15 |  |

L=A + (C) |

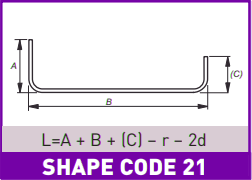

| Shape Code 21 |  |

L=A + B + (C) – r – 2d |

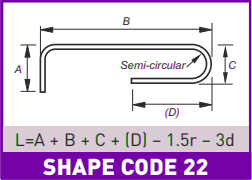

| Shape Code 22 |  |

L=A + B + C + (D) – 1.5r – 3d |

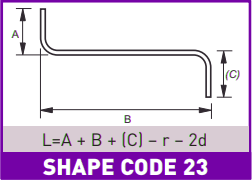

| Shape Code 23 |  |

L=A + B + (C) – r – 2d |

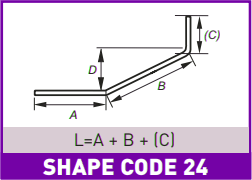

| Shape Code 24 |  |

L=A + B + (c) |

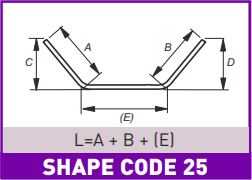

| Shape Code 25 |  |

L=A + B + (E ) |

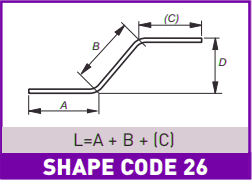

| Shape Code 26 |  |

L=A + B + (c) |

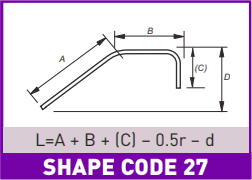

| Shape Code 27 |  |

L=A + B + (C) – 0.5r – d |

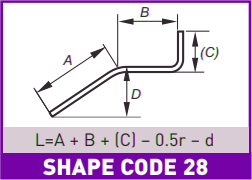

| Shape Code 28 |  |

L=A + B + (C) – 0.5r – d |

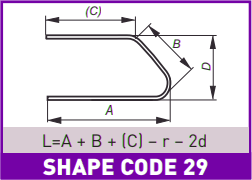

| Shape Code 29 |  |

L=A + B + (C) – r – 2d |

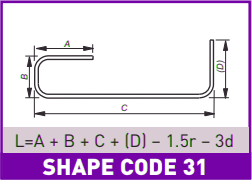

| Shape Code 31 |  |

L=A + B + C + (D) – 1.5r – 3d |

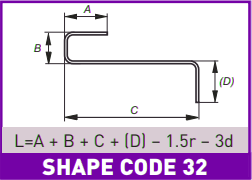

| Shape Code 32 |  |

L=A + B + C + (D) – 1.5r – 3d |

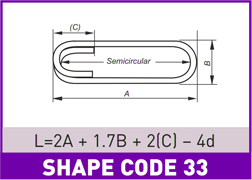

| Shape Code 33 |  |

L=2A + 1.7B + 2(C) – 4d |

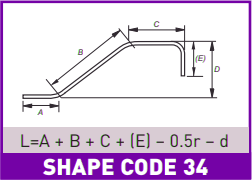

| Shape Code 34 |  |

L=A + B + C + (E) – 0.5r – d |

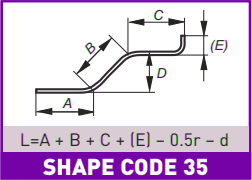

| Shape Code 35 |  |

L=A + B + C + (E) – 0.5r – d |

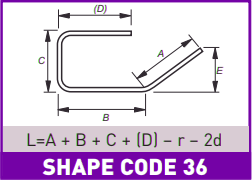

| Shape Code 36 |  |

L=A + B + C + (D) – r – 2d |

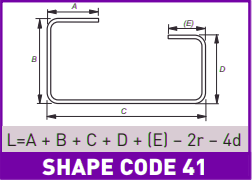

| Shape Code 41 |  |

L=A + B + C + D + (E) – 2r – 4d |

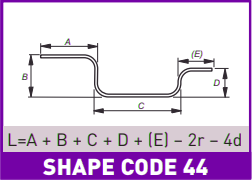

| Shape Code 44 |  |

L=A + B + C + D + (E) – 2r – 4d |

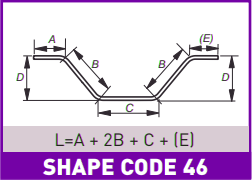

| Shape Code 46 |  |

L=A + 2B + C + (E ) |

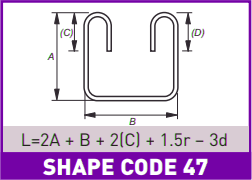

| Shape Code 47 |  |

L=2A + B + 2(C) + 1.5r – 3d |

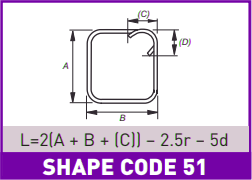

| Shape Code 51 |  |

L=2(A + B + (C)) – 2.5r – 5d |

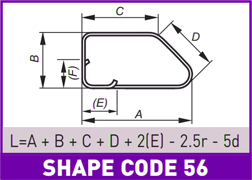

| Shape Code 56 |  |

L=A + B + C + D + 2(E) – 2.5r – 5d |

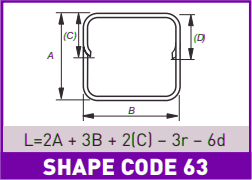

| Shape Code 63 |  |

L=2A + 3B + 2(C) – 3r – 6d |

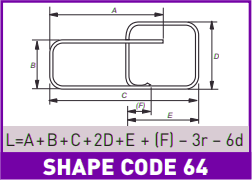

| Shape Code 64 |  |

L=A+B+C+2D+E + (F) – 3r – 6d |

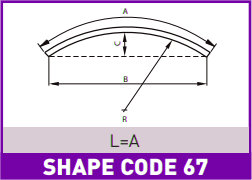

| Shape Code 67 |  |

L=A |

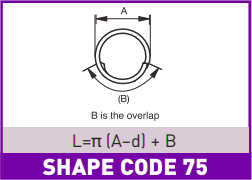

| Shape Code 75 |  |

L=π (A–d) + B |

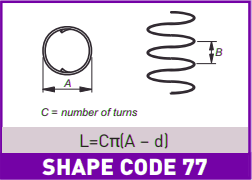

| Shape Code 77 |  |

L=Cπ(A – d) |

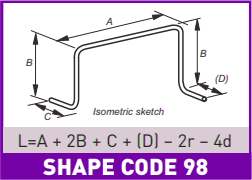

| Shape Code 98 |  |

L=A + 2B + C + (D) – 2r – 4d |

| Shape Code 99 | All other shapes | Require fully dimensioned sketches |

Understanding Rebar Mesh

One important aspect to consider when working with rebar mesh is understanding its configuration and how it contributes to the overall structural integrity of reinforced concrete elements.

Rebar mesh, also known as welded wire reinforcement (WWR), consists of a series of longitudinal and transverse wires that are welded together at their intersections.

The main purpose of rebar mesh is to provide additional tensile strength to concrete structures, helping them resist cracking and improve load-carrying capacity.

The configuration of rebar mesh can vary depending on the specific application and design requirements, with different spacing between wires and varying wire diameters.

It is crucial to ensure proper placement and alignment of rebar mesh within concrete elements during construction in order to achieve maximum effectiveness.

Standard Fabric Types

| Fabric Reference | Longitudinal Bars Size: mm | Pitch mm | Area mm2/m | Transverse Bars Size: mm | Pitch mm | Area mm2/m | Mass Kg/m2 |

|---|---|---|---|---|---|---|---|

| Square Mesh: | |||||||

| A393 | 10 | 200 | 393 | 10 | 200 | 393 | 6.16 |

| A252 | 8 | 200 | 252 | 8 | 200 | 252 | 3.95 |

| A193 | 7 | 200 | 193 | 7 | 200 | 193 | 3.02 |

| A142 | 6 | 200 | 142 | 6 | 200 | 142 | 2.22 |

| Structural Mesh: | |||||||

| B1131 | 12 | 100 | 1131 | 8 | 200 | 252 | 10.9 |

| B785 | 10 | 100 | 785 | 8 | 200 | 252 | 8.14 |

| B503 | 8 | 100 | 503 | 8 | 200 | 252 | 5.93 |

| B385 | 7 | 100 | 385 | 7 | 200 | 193 | 4.53 |

| B283 | 6 | 100 | 283 | 7 | 200 | 193 | 3.73 |

| Long Mesh: | |||||||

| C785 | 10 | 100 | 785 | 6 | 400 | 70.8 | 6.72 |

| C636 | 9 | 100 | 636 | 6 | 400 | 70.8 | 5.55 |

| C503 | 8 | 100 | 503 | 6 | 400 | 70.8 | 4.51 |

| C385 | 7 | 100 | 385 | 6 | 400 | 70.8 | 3.58 |

| C283 | 6 | 100 | 283 | 6 | 400 | 70.8 | 2.78 |

| Wrapping Mesh: | |||||||

| D98 | 5 | 200 | 98 | 5 | 200 | 98 | 1.54 |

| D49 | 2.5 | 100 | 49 | 2.5 | 100 | 49 | 0.77 |

| D49 | 2.5 | 100 | 49 | 2.5 | 100 | 49 | 0.77 |

Rebar cutting Machines and Equipements

Rebar cutting machines and equipment play a crucial role in the construction industry. They provide efficient and accurate means of cutting rebar to specific lengths, ensuring that it can be properly incorporated into reinforced concrete structures. These machines are designed to handle the high tensile strength of rebar and offer various cutting mechanisms such as hydraulic or electric shearing.

Here are three key features of rebar cutting machines:

- Precise Cutting: Rebar cutting machines use advanced technology to achieve precise and clean cuts. This minimizes wastage and ensures the accuracy of the final length.

- High Productivity: These machines are capable of cutting multiple bars simultaneously. This increases productivity and reduces labor-intensive manual processes.

- Safety Measures: Rebar cutting machines come equipped with safety features. These include emergency stops, protective guards, and non-slip surfaces to ensure operator safety during operation.

Bar Cutting Machine

A Bar Cutting Machine is a powerful tool used in construction to precisely cut steel bars. This machine efficiently slices through metal, enhancing construction speed and accuracy. Operators find it easy to use, as it simplifies the task and ensures consistent results. It plays a vital role in creating robust and stable structures.

Rebar Bending Machine

A Rebar Bending Machine is a crucial apparatus in construction that actively bends steel reinforcement bars with precision. This machine streamlines the bending process, enabling construction workers to create custom-shaped rebars effortlessly. It plays a pivotal role in ensuring the structural integrity and stability of buildings and infrastructure, contributing to efficient construction practices.

Rebar Hand Cutter

A Rebar Hand Cutter is a handy tool used in construction for cutting steel reinforcement bars manually. It offers a straightforward and portable solution for on-site cutting needs. Construction workers can easily operate it to achieve precise cuts, making it a valuable tool for various construction tasks. Its simplicity and reliability make it a go-to choice for small-scale cutting requirements in the construction industry.

Overall, rebar-cutting machines are essential tools for construction projects. They enhance efficiency, accuracy, and worker safety in handling reinforcing steel bars.

Conclusion

In conclusion, rebar plays a vital role in concrete structures, providing strength and stability. Its evolution from simple iron rods to various types and shapes highlights its importance in construction.

Understanding rebar mesh and shape codes is crucial for ensuring proper reinforcement. Rebar-cutting machines and equipment help streamline the construction process.

As we continue to advance in technology, the use of rebar will undoubtedly become more efficient and effective, leading to even stronger and safer buildings.

So next time you see a towering structure, remember that it’s the hidden reinforcement of rebar that keeps it standing tall.